high efficiency

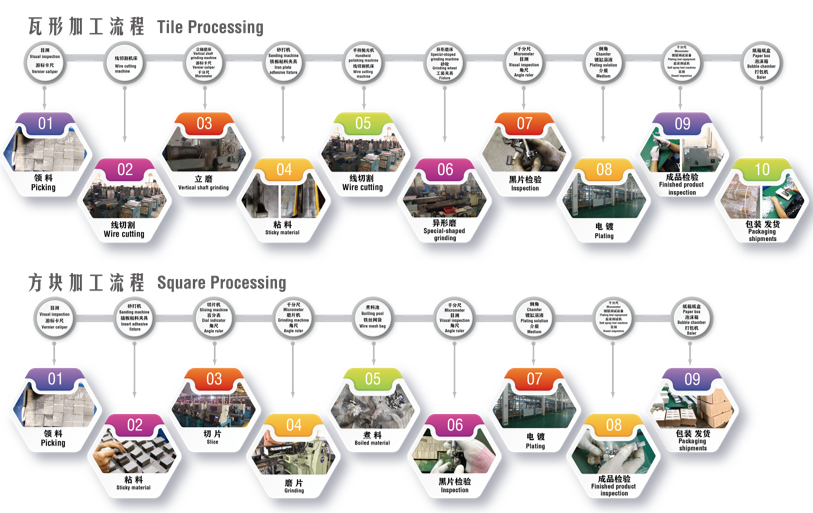

1. Stick the material with asbestos board. Wipe the product surface clean, so that the asbestos board is not easy to fall off.

2, slice

3. Grinder

4. Wipe the material with dry sawdust and select the knife mark.

5. Bake and then cook, mainly to remove asbestos board and glue traces

6. Check, select flatness and screen whether there is missing angle

7. Packing or packing, shipment

1. Confirmation before operation

2. Startup inspection

3. Disk cleaning

4. Select the initial machining surface

5. Discharging

6. Machine tool adjustment

7. Feed machining

8. Reclaim

9. Inspection record

10. Shutdown and cleaning

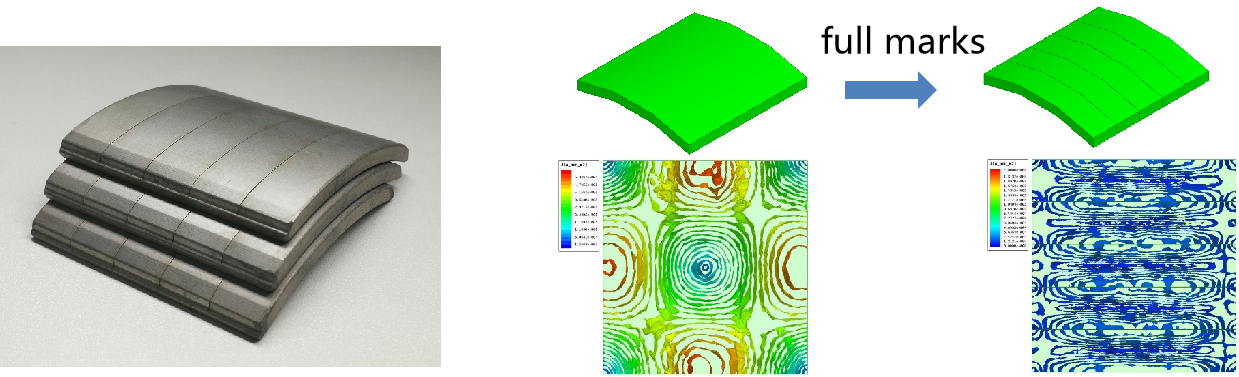

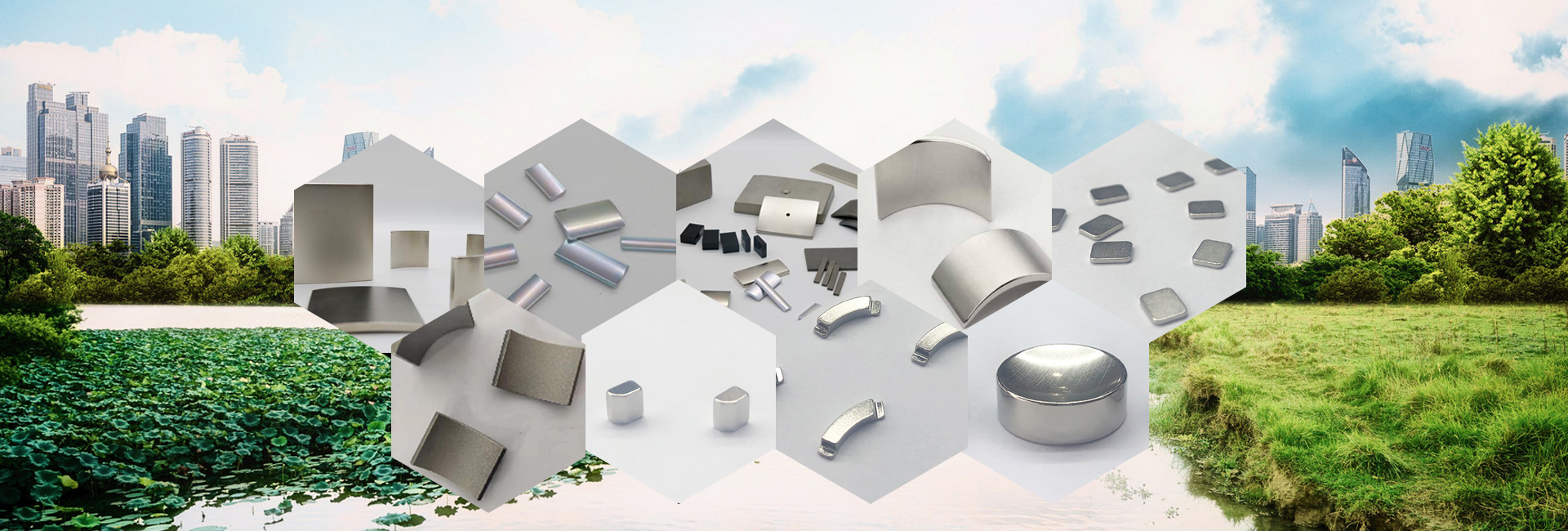

Strong R & D capability

Have experienced technical team, according to different needs of customers, develop and debug new production technology to meet different needs of the market.

First class equipment

According to the different needs of the market, constantly update equipment and technology, walking in the front of the magnetic industry.

1. Turn on the power

2. Check whether the equipment is abnormal (whether oil, water and gas are enough)

3. Loading and unloading take-up and setting out wheels (the upper is the take-up wheel, the lower is the take-up wheel)

4. Load and unload the roller (install the new roller and input the roller diameter "Parameter settings")

5. Winding operation

6.Trial cut (1-1.5 hours for new roller)

7. Cutting operation: A. gluing B. feeding C. cutting is required in "parameter setting" Height, patching height, precise setting D. turn on the oil pump, turn on the "disconnection detection" and start cutting E. after cutting and blanking, pay attention to observe whether there is line jamming Blanking

8. Shutdown

9. test

1. Incoming inspection: use micrometer to check whether the incoming dimension is consistent with the product specification on the processing drawing and construction sheet.

2. Confirm the equipment status and check whether the water circuit is normal. Before starting the machine, check the equipment, add oil and lubricate the equipment according to the regulations, check whether the oil pressure, oil circuit, oil volume, etc. are normal, and whether the oil quality is good

3. Preparation for arc grinding: Inspection and repair of grinding wheel; installation and inspection of fixture; opening of water pump; opening of grinding head.

4. Loading, trial grinding. The workpiece shall be put into the fixture for grinding in turn. Let the product rough grind first, and then gradually grind to the required size.

5. Batch grinding. After the trial grinding products are qualified, they can be processed in batches

6. Inspection: according to the processing order and drawings, check the size of the ground products, and place the qualified products and unqualified products in different designated areas. Record the first inspection, patrol inspection and completion inspection.

7. Shut down and clean. Shut down the machine, put the auxiliary tools and measuring tools in the designated position, and clean the surrounding of the equipment.

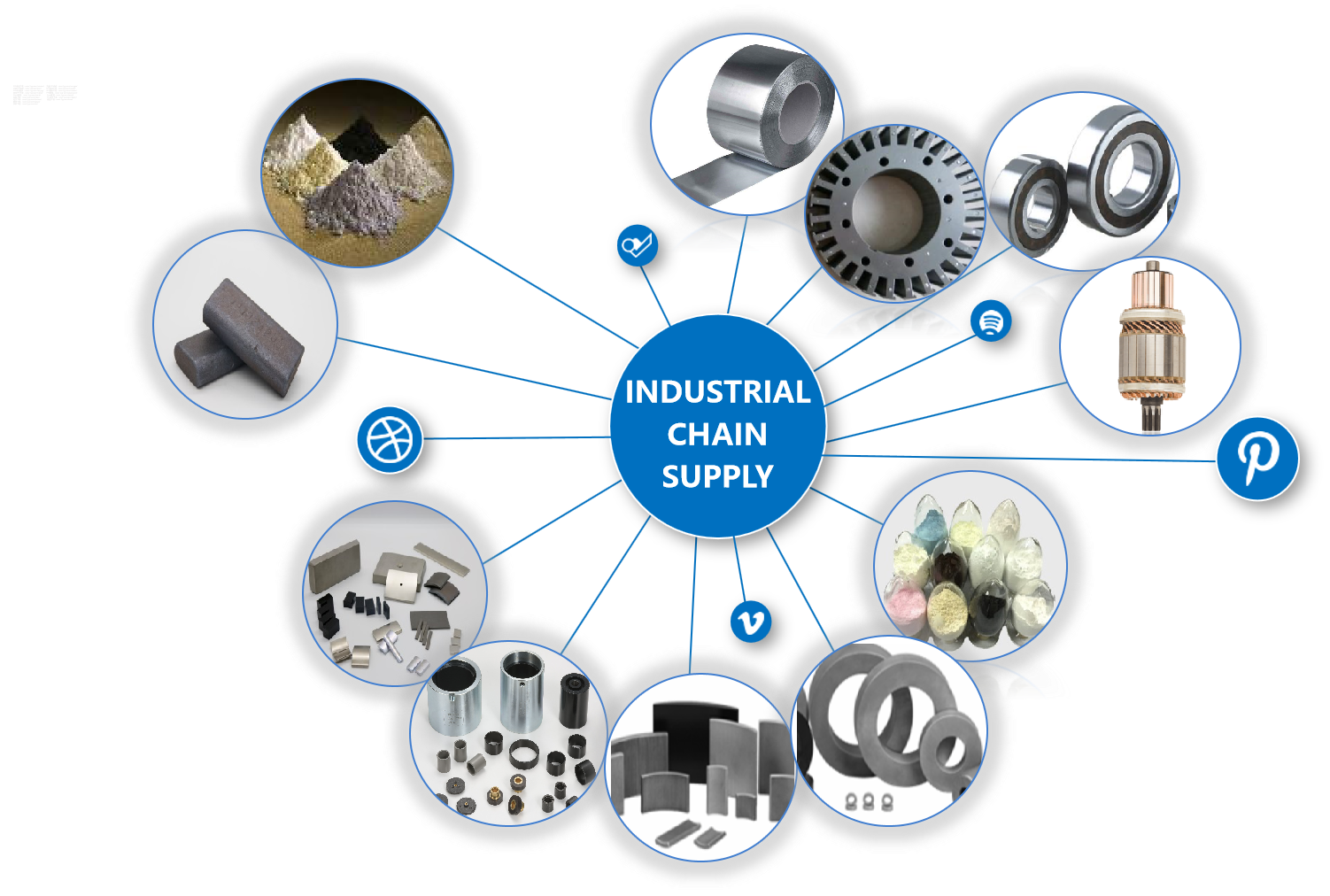

The company has large-scale production equipment and perfect quality management system. It is the designated partner of China's top 500 enterprises, Jinlong rare earth, a wholly-owned subsidiary of Xiamen tungsten industry, one of the six national rare earth groups, Ningbo Yunsheng, the world's largest rare earth permanent magnet material manufacturer, and other famous domestic production enterprises. Jinchi trading is committed to providing customers with satisfactory products and services, and providing customers with the most professional NdFeB processing program. Our products are widely used in wind power generation, automobile electric drive, household appliances, energy-saving elevator, medical equipment, it communication, servo motor, industrial robot and other fields. The product quality represented by 52h, 50huh, 42eh, 45eh, 38ah and 48h, 50h without heavy rare earth has reached the international advanced level.

Perfect quality assurance system

There is a standard and perfect quality team to ensure the high quality and efficiency of products.

关注官方微信

关注官方微信