Quality Control

> Quality Assurance

One touch projector

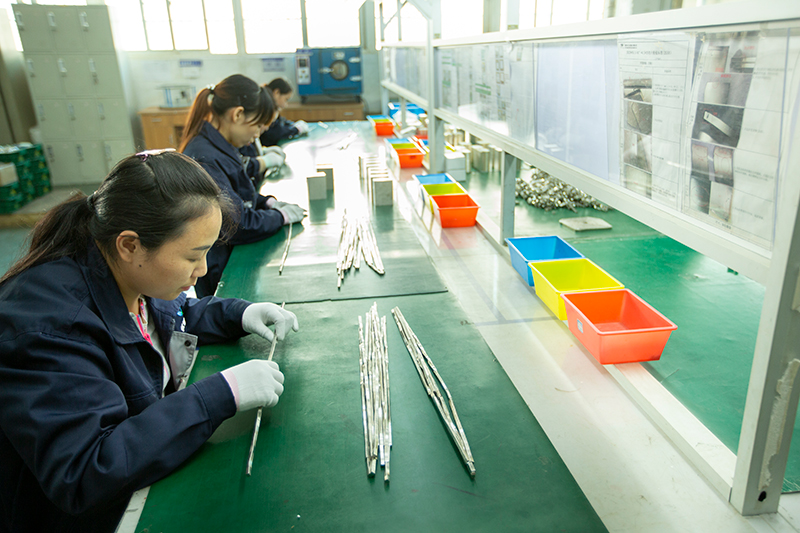

The improvement of product quality and efficiency is inseparable from the efficient management of production equipment and production specifications. In the process of management, it is essential to detect the qualification rate of semi-finished products and finished products. When we require more accurate data of two-dimensional dimension of products, we need to obtain accurate parameters of two-dimensional dimension of products through detection means. At the same time of ensuring product quality, it also improves the efficiency of product detection

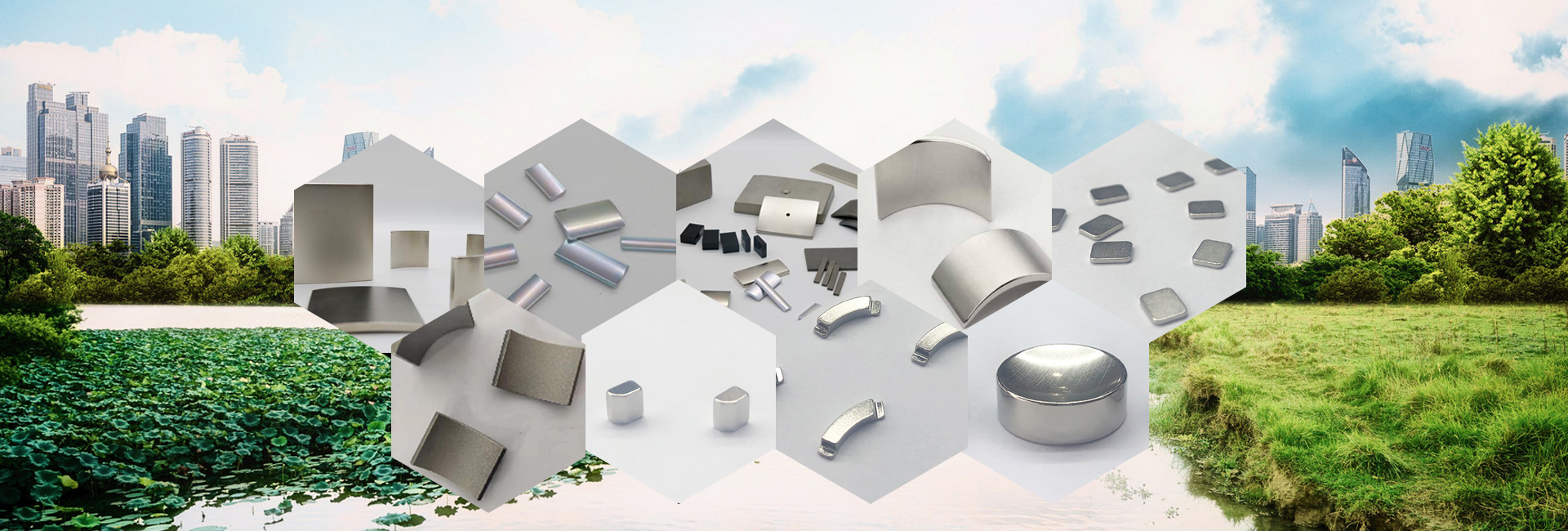

Size sorting, according to the requirements of product size accuracy, different configurations are selected,100% full inspection of each product, such as inner and outer diameter, length and width, R degree, concentricity Degree, rectangularity, etc.

Color sorting, setting color standard, all products that do not meet the requirements will be classified Open, such as color difference, color degree, etc.

For the detection of different incoming products, products other than OK products shall be removed by ng, such as leakage process Mixing and so on.

Product defect detection, develop defect limit sample, and make non-conforming products Remove, such as mechanical defects, angle dropping, crushing, scratches, etc. Appearance defects: such as stains, bubbles, oxidation, etc.

Salt spray test is mainly used for surface treatment of various materials, including coating, electroplating, inorganic and organic coating, cathodic treatment of antirust oil and other anti-corrosion treatment, to test the corrosion resistance of its products.

It is mainly responsible for product inspection, testing, magnetization, packaging, delivery, etc., with a perfect quality inspection and testing system and the best packaging and packaging scheme,Equipped with efficient transportation team.

关注官方微信

关注官方微信